First, Pneumatic PTFE Sealing Butterfly Valve Products Overview

AT Pneumatic PTFE Butterfly Valve Consists of PTFE sealing butterfly valve, stainless steel valve plate and valve stem. Pneumatic PTFE sealing butterfly valve is suitable for temperature less than 150 DEG C, Weak corrosion or cleanliness conditions have certain requirements, in food, medicine, chemical, petroleum, electric power, papermaking, water supply and drainage, gas pipes to regulate the flow and closure of the role of media.

Main Features Of AT Pneumatic PTFE Butterfly Valve

1, The design is novel, reasonable, unique structure, light weight, quick opening and closing.

2, Small operation torque, easy operation, labor-saving and smart.

3, Can be installed in any location, convenient maintenance.

4, Seals can be replaced, sealing performance is reliable, to achieve two-way sealing zero leakage.

5, Sealing material aging resistance, corrosion resistance, long service life and so on.

Two, Main Technical Parameters Of Pneumatic PTFE Butterfly Valve

1, Valve Body

| Type of Body | Straight Through Casting Valve Body |

|---|

| Nominal Diameter | DN50~1200mm |

|---|

| Nominal Pressure | PN 0.6����、1.0、1.6 MPa |

|---|

| Flange Standard | GB��、JB�、HG、ANSI��、JIS |

|---|

| Connection Form | Pair Clamp Type, Flange Type |

|---|

| Gland Type | One-piece |

|---|

| Sealing Filler | V PTFE Packing and Flexible Graphite Filler |

|---|

2, Valve Internals

| Valve Plate Form | Vertical Plate (Butterfly) |

|---|

| Flow Characteristics | Switch Type: Linear; Regulating Type: Approximate Equal White Ratio |

|---|

3, Executive Agencies

| Actuator Type | GT Series, SR Series, AT Series, AW Series Single and Double Acting Pneumatic Actuators |

|---|

| Gas Supply Pressure | 400~700KPa |

|---|

| Air Connection | G1/4"��、G1/8"���、G3/8"、G1/2" |

|---|

| Ambient Temperature | -30~+70℃ |

|---|

| Single Acting Actuator: Gas Shut Off (B) - Valve opening (FO) when gas is out of breath; gas open (K) - valve position off (FC) when air is out of breath

Double Acting Actuator: Gas Shut off (B) - valve position holding (FL) when gas lost; gas open (K) - valve position holding (FL) when lost air |

|---|

| Fitting Accessories | Positioner, Solenoid Valve, Air Filter Pressure Reducer, Retaining Valve, Stroke Switch, Valve Position Conveyor, Hand Wheel Mechanism, etc. |

|---|

Three, Main Performance Index Of Pneumatic PTFE Butterfly Valve

| Nominal Diameter | DN(mm) | 50~2000 |

|---|

| Nominal Pressure | PN(MPa) | 0.6 | 1.0 | 1.6 |

| Test Pressure | Strength Test | 0.9 | 1.5 | 2.4 |

| Sealing Test | 0.66 | 1.1 | 1.76 |

| Airtight Sealing Test | 0.6 | 0.6 | 0.6 |

| Applicable Medium | Air, Water, Sewage, Steam, Gas, Oil and so on. |

| Driving Form | Manual, Worm and Worm Gear Drive, Pneumatic Drive, Electric Drive. |

Four, Pneumatic PTFE Butterfly Valve Parts Material

| Part Name | Material Science |

|---|

| Valve Body | Ductile Cast Steel, Cast Steel, Alloy Steel, Stainless Steel |

| Disc | Grey Cast Iron, Ductile Cast Steel, Cast Steel, Stainless Steel and Special Materials |

| Teflon�、PTFE |

| The Stem | 2Cr13、Stainless Steel |

| Filler | O-ring |

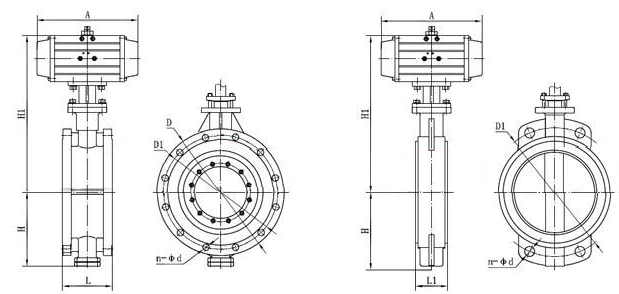

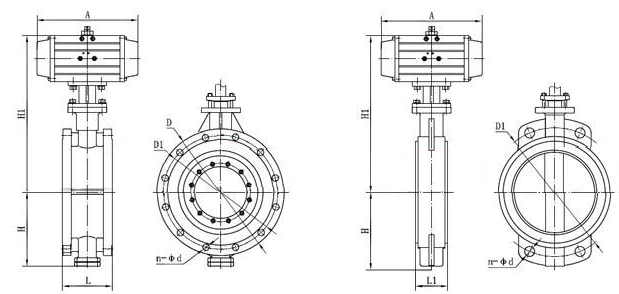

Shape Connection Size

Nominal

Diameter

DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 |

|---|

| L | 90 | 90 | 100 | 115 | 130 | 140 | 150 | 250 | 270 | 290 | 310 | 330 | 350 | 390 | 430 | 470 | 500 | 550 |

| L1 | 43 | 46 | 49 | 56 | 64 | 70 | 71 | 76 | 83 | 92 | 102 | 113 | 127 | 154 | 165 | 190 | 203 | 216 |

| H | Flange Type | 63 | 70 | 83 | 105 | 115 | 137 | 164 | 206 | 230 | 248 | 289 | 320 | 343 | 413 | 478 | 525 | 585 | 640 |

| Clip Type | 63 | 70 | 83 | 105 | 115 | 137 | 164 | 206 | 230 | 248 | 289 | 320 | 343 | 413 | 478 | 525 | 585 | 640 |

| n-φd | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | 16-26 | 16-30 | 20-30 | 20-33 | 20-36 | 24-36 | 24-39 | 28-39 | 28-42 |

| H1 | It depends on the executing agency |

| A | According to the torque required by the valve, the configuration of different models, the size of the shape is not the same |

| D | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 | 640 | 715 | 840 | 910 | 1025 | 1125 | 1255 |

| D1 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | 1050 | 1170 |

Note: the size of the table is data without standard accessories. In addition, technical innovation parameters may be changed due to product improvement. Please consult the technical department for the latest data.

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552